No doubt even though effects of first and second wave of Covid19 died down, effects on supply log jam and labour force did not streamline till recently. This caused product availability issues all throughout.

The Institute for Supply Management (ISM) recent survey suggested some improvement in labour supply, with a gauge of factory employment rising to an eight-month high. Still shortages of critical lowest-tier materials, high commodity prices and difficulties in transporting products continue to plague reliable consumption. The survey does not fully capture the impact of the Omicron COVID-19 variant, which is rapidly spreading across the United States and abroad. Sky-rocketing infections could force workers to stay home and halt the tentative supply-chain progress. All of the six biggest manufacturing industries – chemical products, fabricated metal products, computer and electronic products, food, transportation equipment, and petroleum and coal products – reported moderate-to-strong growth.

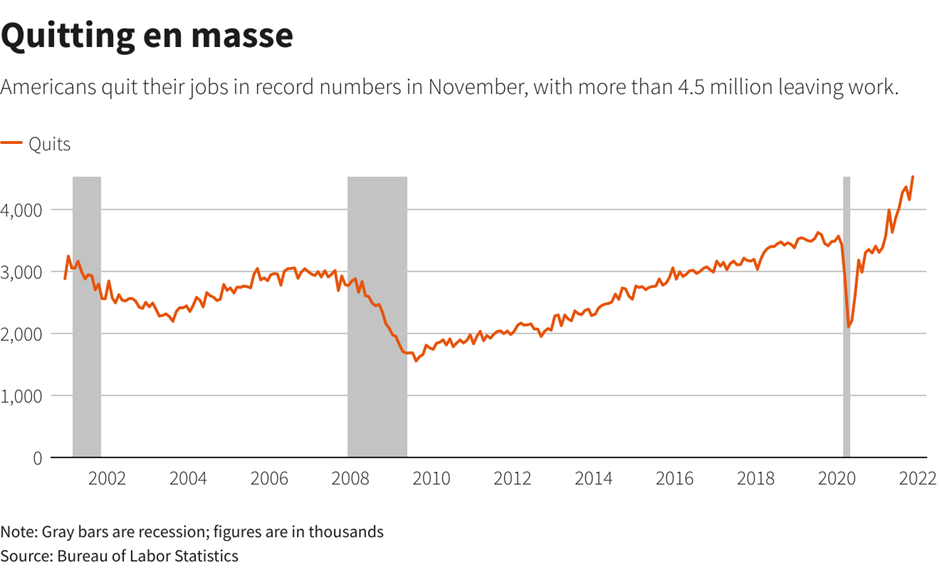

Factories hired more workers, but turnover rates remained high, a trend which manufacturers said started in August, 2021. Americans voluntarily quit their jobs in November, 2021 which will put pressure on businesses to raise wages to attract workers.

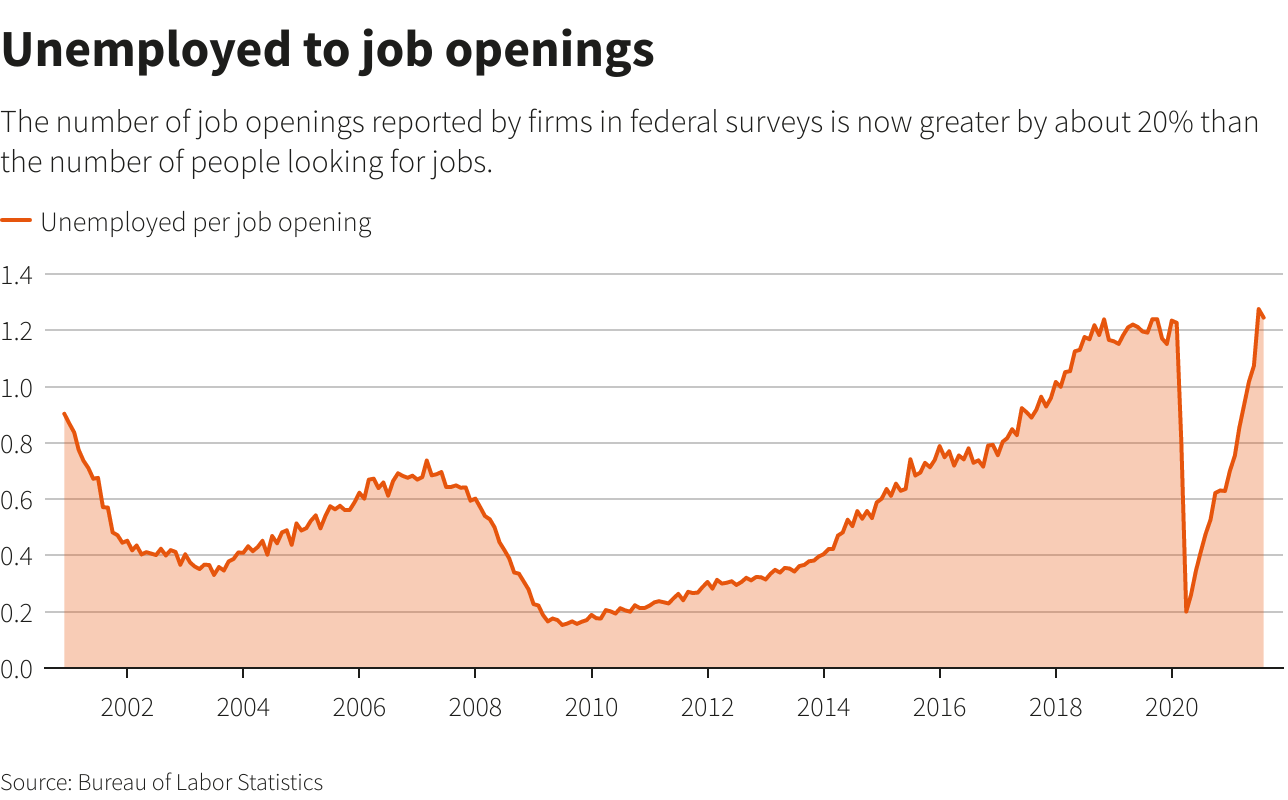

The below charts explain the same:

NPowersU Expert Opinion

Currently everything around the world is so unpredictable; it seems like a never ending see-saw ride. Some issues settled then new one crops up, not taking into account the new Covid19 variants being reported around the world. However a seasoned CEO will enjoy this period which will call for continuous ‘Out of the Box’ thinking.

It feels Covid has taken cue from humans who multi-task like working on laptop, answering phones and punching messages or viewing videos on social media – all at the same time. Hope Humans and Covid learn the importance on focussing of one thing in hand rather chasing two pigeons in the bush.

Related Links: